Ámbitos de Actuación

-

Obras Hidráulicas

Llevamos inyectadas más de 1.500 toneladas de resinas en más de 250 presas repartidas por todo el mundo.

-

Obras Subterráneas

La tecnología HCC permite la impermeabilización y refuerzo de todo tipo de obras subterráneas

-

Cimentación de Turbinas Eólicas

La tecnología desarrollada por HCC, hace más de una década, ha permitido la reparación, hasta la fecha, de más de 450 cimentaciones.

-

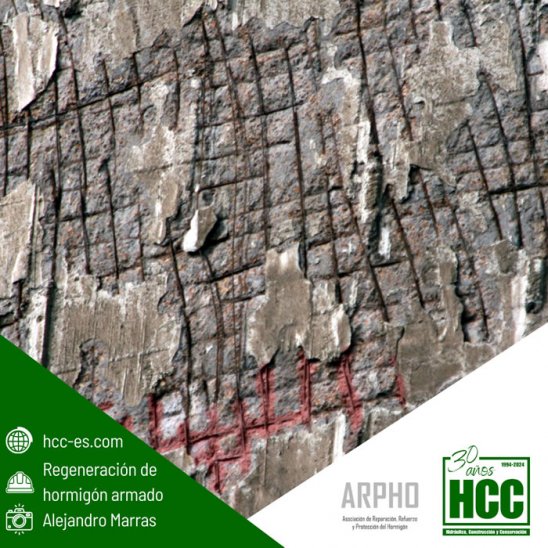

Puertos y Edificios

Trabajamos en todo tipo de industria o puertos, cuidando del hormigón, impermeabilizando, reforzando y, por lo tanto, extendiendo la vida útil de las instalaciones.

Actualidad

Quiénes somos

HCC es una empresa española, híbrido entre Ingeniería y Constructora, presente en diversos países de Oriente, Europa y América, especializada en el proyecto, mantenimiento y reparación, esencialmente de obras hidráulicas, obras subterráneas, puertos y edificaciones así como en la obra civil asociada a las turbinas eólicas. Contamos con delegaciones activas en diversos países de Latinoamérica y Oriente.